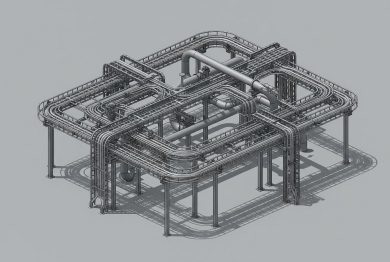

Seamless Modeling

Powering Projects with Intelligent Electrical BIM Modeling

ASC Technology Solutions also offers future-ready Electrical BIM Services with the same level of accuracy and intelligence that we apply to our Mechanical BIM Services and the rest of our Mechanical BIM processes.

We have integrated electrical models that provide the smooth cooperation of engineers, architects, and contractors, and assist in reducing design conflicts from the very beginning. Through the incorporation of Mechanical System Modeling Services, Mechanical Drafting Services, and Mechanical Fabrication Drawing Services, we produce construction-ready mechanical-related electrical BIM products that advance design realism, decrease rework, and improve project efficiencies. Designed to support both detailed electrical layout and used to add to the multidisciplinary coordination of solutions, our models provide a foundation to create smarter project delivery, creating a smooth correspondence with complementary trades such as HVAC and mechanical systems.

Impactful design

Compliance-Driven, Globally Aligned Electrical BIM Expertise

The Electrical BIM Services at ASC Technology Solutions are guided by the rigorous international standards we are ensuring that each of the projects is internationally compliant, technically viable, and ready to execute the work. With the help of experience in Mechanical BIM Services, rather advanced practices of Mech BIM, our team provides the correct electrical models, which are easy to integrate into the multidisciplinary BIM platforms. Our expertise in Mechanical Quantity Takeoff, Mechanical As-built Design Services, Mechanical Shop Drawing Services, and even HVAC Duct Shop Drawing Services gives us the capacity to give full-scale precision in all the building systems. Creating coherent electrical models like circuit-level detailing and clash-free layouts, we assist our customers with working towards greater constructability, improved communication, and simplified processes facilitated by data-driven and integrated BIM intelligence.

Transformative Solutions

Our Extensive Electrical BIM Services

Turning complex ideas into practical, high-quality outcomes while empowering clients to achieve success with confidence and clarity.

Electrical Equipment Modeling

ASC Technology Solutions provides accurate 3D models of many electrical components, which are electrical systems, lighting, distribution boards, switchboards, load banks, busducts, cable trays, and ladders. All models are designed with ease of understanding, assembly, and alignment to trade- these designs are indeed a great fit to our experience in Mechanical Coordination Services as a full project integrator.

Communication & Data Device Modeling

Our BIM models are very comprehensive and detailed in the areas of communication networks, including cable baskets, secured ducts, data equipment, and routing systems. Each component is modeled in the exact placement and specifications, and it facilitates perfect coordination, just as Mechanical System Coordination Services organizes mechanical layouts in any discipline.

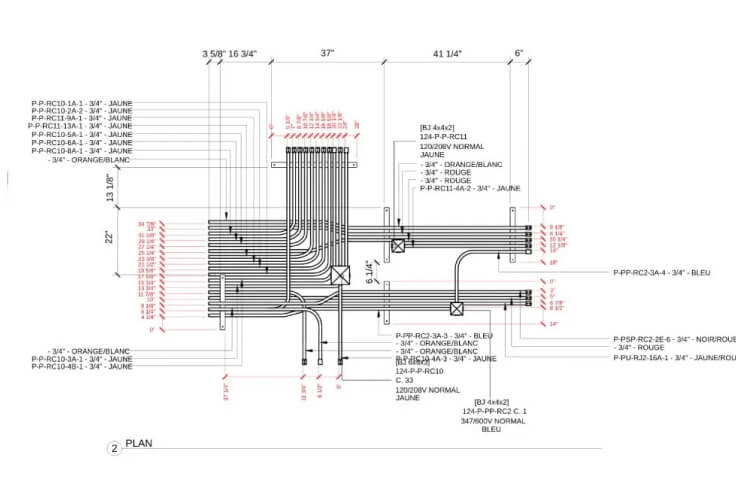

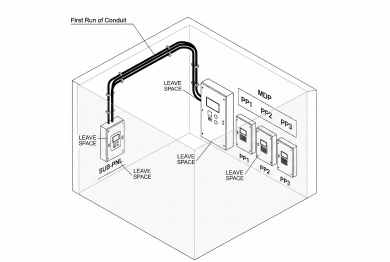

Conduit Layout Modeling

Our team comes up with detailed 3D BIM models used to lay conduits to follow accurate electrical installations. Each routing is well coordinated with architectural, mechanical, plumbing, and fire-protection systems to pull out system conflicts. This workflow is coordination-based based which is aligned to our Mechanical System Clash Detection Services capabilities.

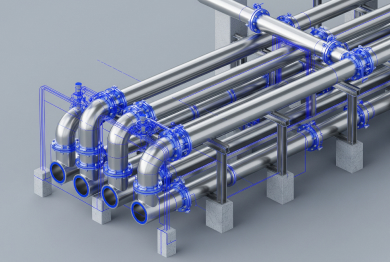

External Site Modeling

ASC models finish external electrical facilities, such as LV / HV systems, communication pits, duct banks, and cable trenches. These data-intensive models assist in mitigating any excavation-related risks and in making sure that all the underground utilities are properly designed, facilitating a better integration with other services, such as HVAC BIM Services, to achieve the fullest MEP synergy.

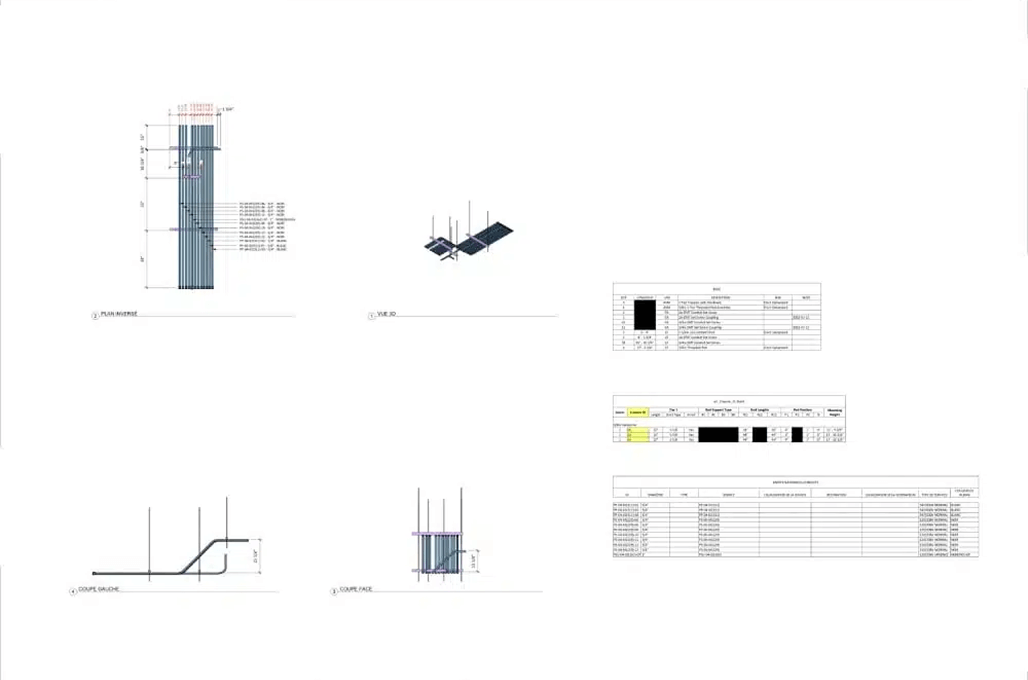

Hangers & Supports Modeling

We lay out and model complete hanger and support equipment of electrical layouts, such as cable trays, ladders, lighting hangers, and wall-mounted supports. Our precise models are easy to install and integrate all supports with the rest of the MEP trades and supplement other workflows like 3D HVAC Modeling Services.

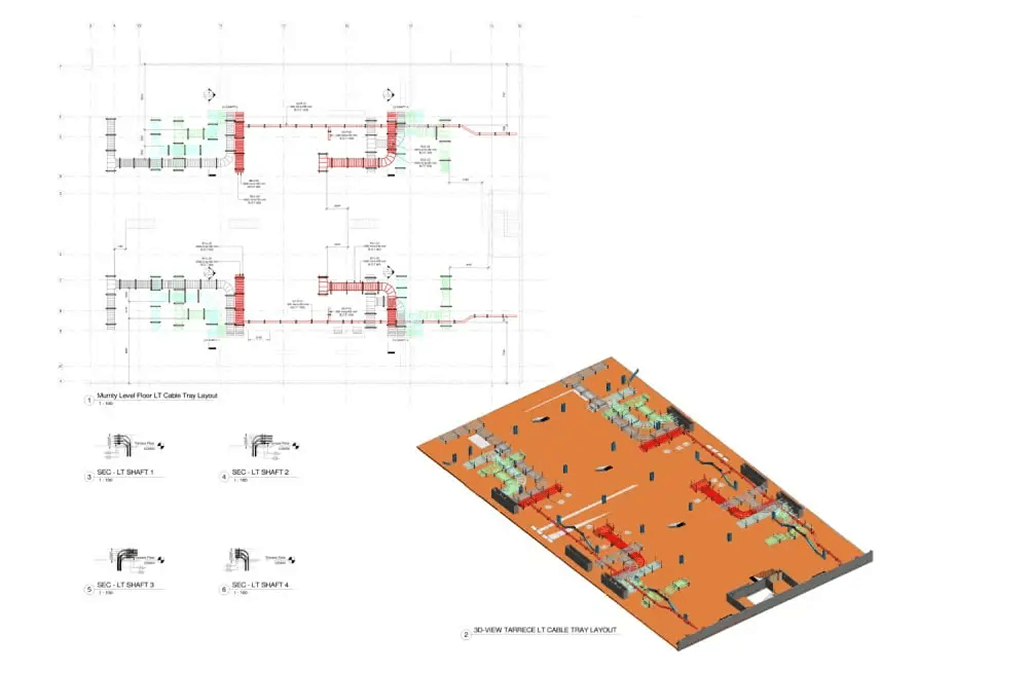

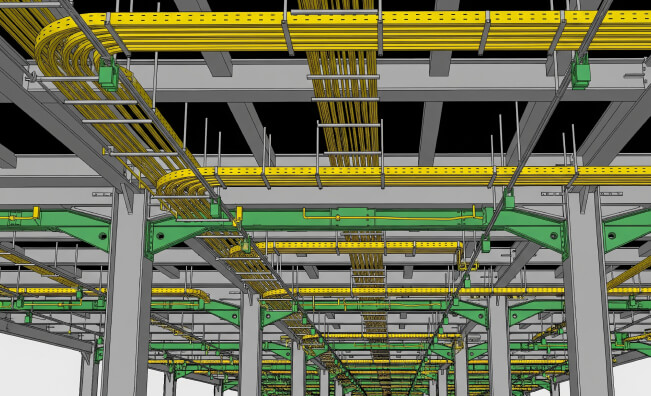

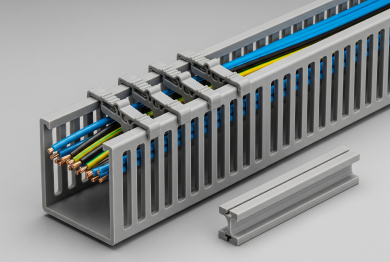

Cable Tray Modeling

We generate high-quality, conflict-free 3D representations of cable tray systems that are cost-effective in terms of routing and also aligned with the rest of the disciplines. This minimizes any rework on site, guarantees that there is feasibility, and also enhances the constructability of the whole MEP layout.

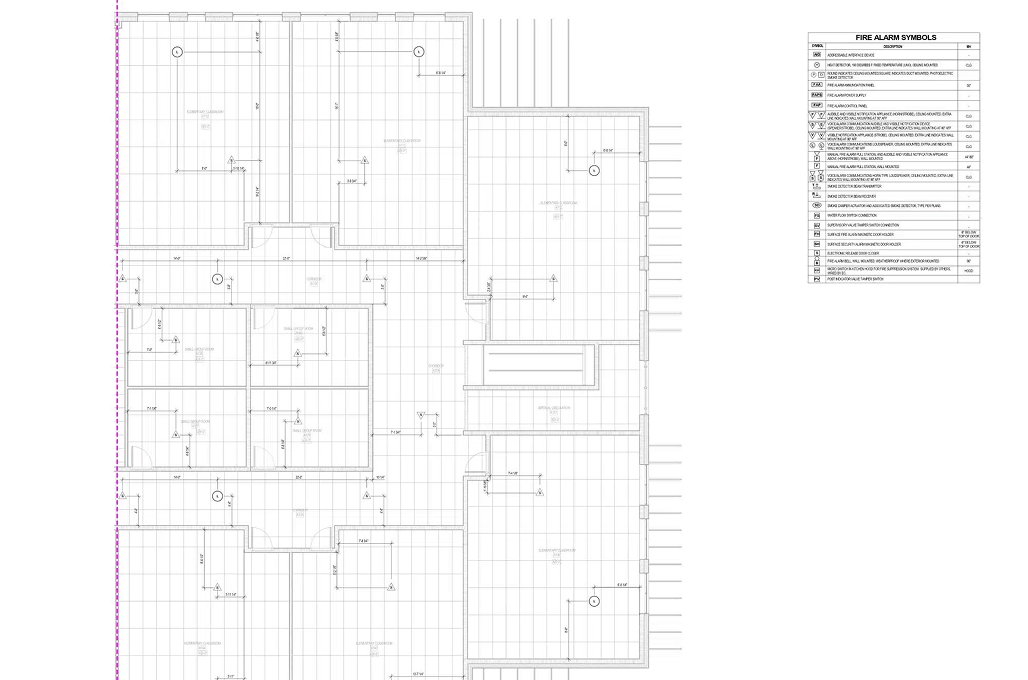

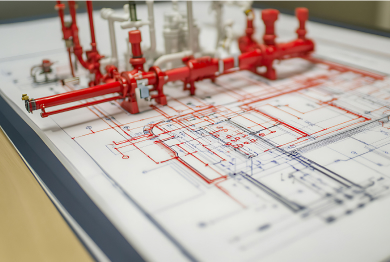

Fire Alarm System Modeling

ASC creates code-compliant and smart electronic BIM models of the fire alarm system, and the locations of devices, wiring, and parts of the system. All models are well coordinated with all the services so that they can be installed with ease, do a more careful safety planning, and they can also integrate an effective system.

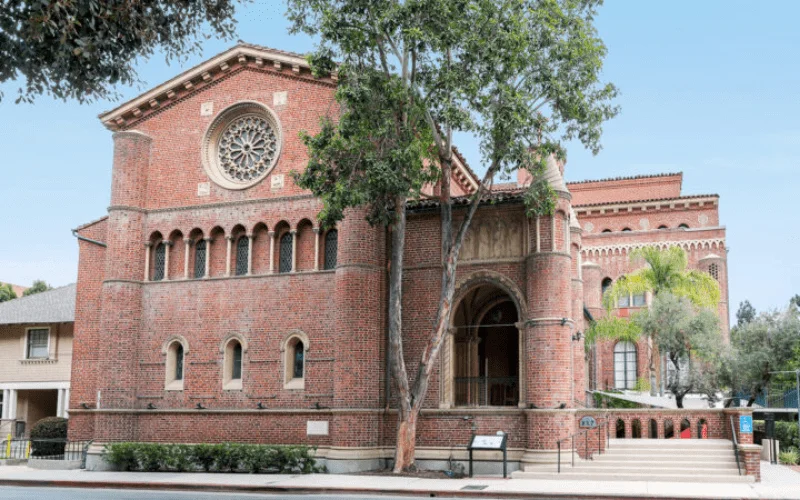

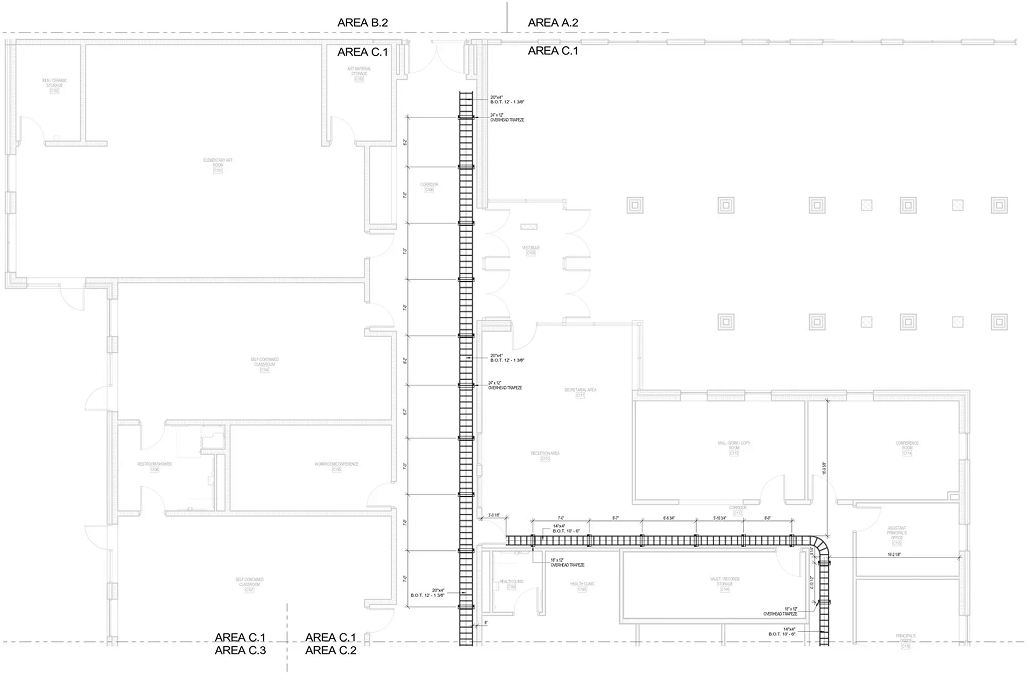

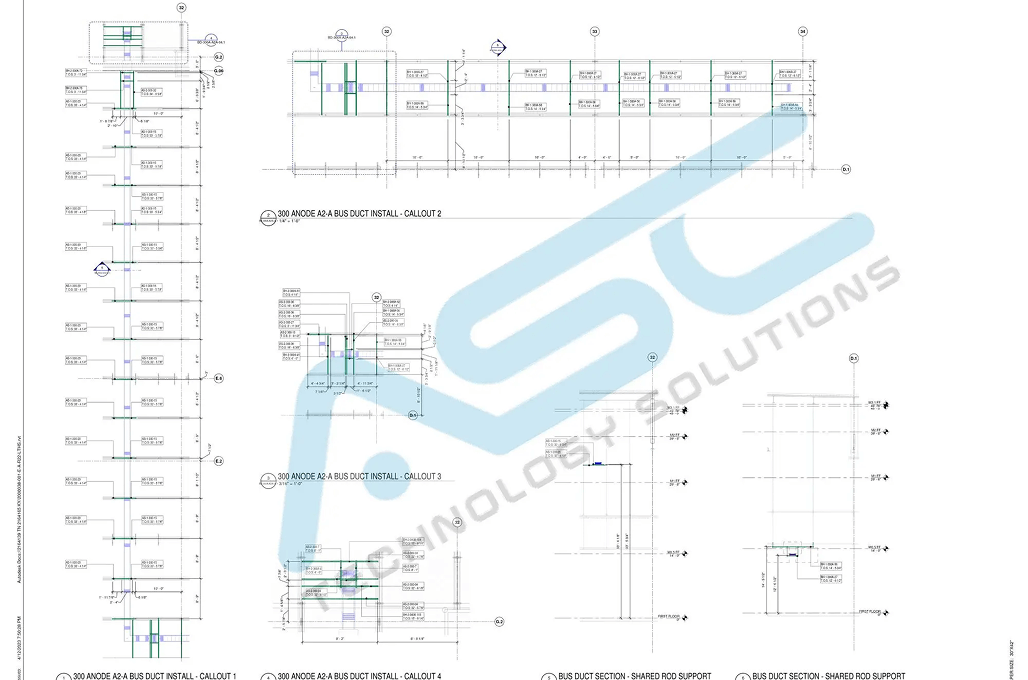

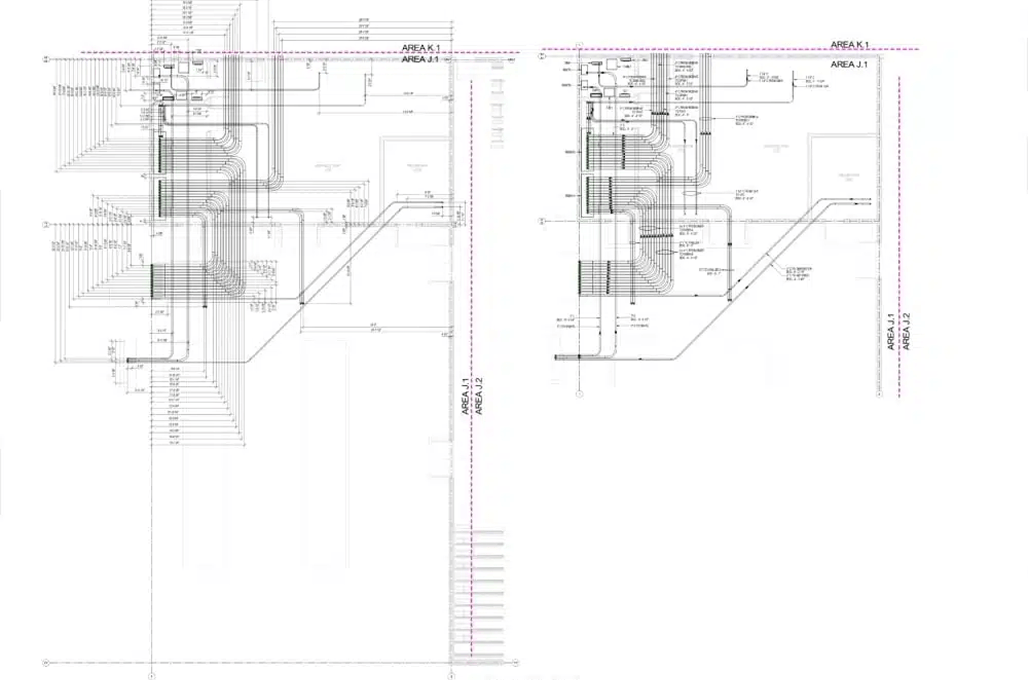

Featured Projects

Inspiring Modern Spaces, Built to Last

Take a glimpse into our thoughtfully planned and precisely executed work, which sets our standards apart.

Unlock advantages

Benefit Yourself By Working With Us

- Greater interweaving of all trades with our Electrical BIM models being seamlessly integrated with Mechanical BIM Services, plumbing, fire protection, and structural elements, reducing clashes and enhancing the flow of the structure.

- Earlier detection of issues leads to reduced project costs, which removes the rework and helps in more productive planning and resource assignment.

- Improved total efficiency of the project through pre-construct installation difficulties identification before construction commences to achieve easy on-site execution and improved sequencing.

- Enhanced safety with elaborate modeling of fire alarm designs, emergency systems, and design checks based on compliance, to reduce risks throughout the construction process and operational risks.

- Improved visualization through correct 3D electrical system models that enable the stakeholders to make sense of layouts, routing, and equipment positioning in the initial stages of the design.

- Enhanced trade alignment through integration of the lessons learnt in Mechanical BIM, Mechanical Coordination Services, and Mechanical System Coordination Services to ensure uniformity of the MEP systems.

- Better clash-free designs with better coordinated workflows that complement Mechanical System Clash Detection Services and HVAC BIM Services to deliver the entire project.

our working process

Creating Remarkable Spaces with Precision

We have combined technical skills with real project knowledge to provide quality BIM-based solutions. From early concept to detailed execution, we strive to make the right decisions, collaborate, and create long-term value that helps make decisions smarter and project-based results successful.

01

Concept & Consultation

The first step we take towards your project is to know about your objectives and the technical challenges of the project. Our professionals work hand-in-hand with the stakeholders to establish the scope, expectations, and a solid ground for efficient and quality delivery of the BIM.

02

Design & Planning

Our team is able to produce coordinated BIM models that are clear and precise, reflecting design intent. We also plan and validate to ensure there is an optimized workflow, fewer conflicts, and improved coordination of all project disciplines.

03

Development & Execution

We have approved designs that we convert to fine BIM models, ready to construct. Our execution phase stresses compliance and accuracy which the effective coordination is achieved, and the rework is reduced, enabling projects to proceed smoothly.

04

Final Delivery & Handover

We provide complete validated BIM models and documents depending on the project requirements. We have a well-organized handover approach that guarantees a seamless transition operation, and proper data accessibility with long-term functionality to the construction, operation, and facility management teams.

- 2k+

Align with Businesses that Choose Quality

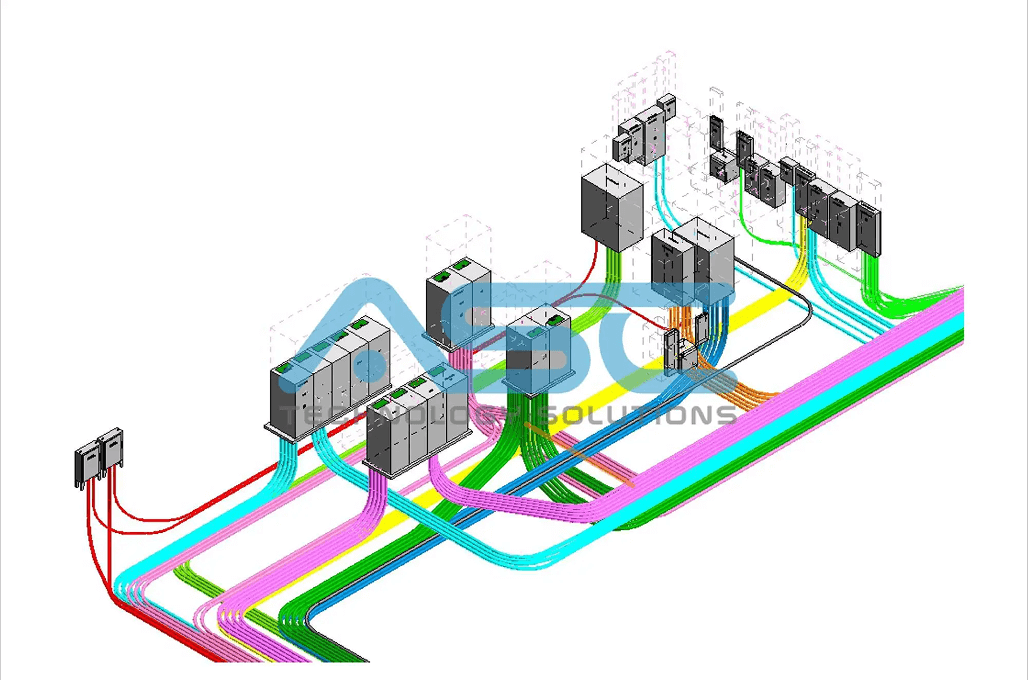

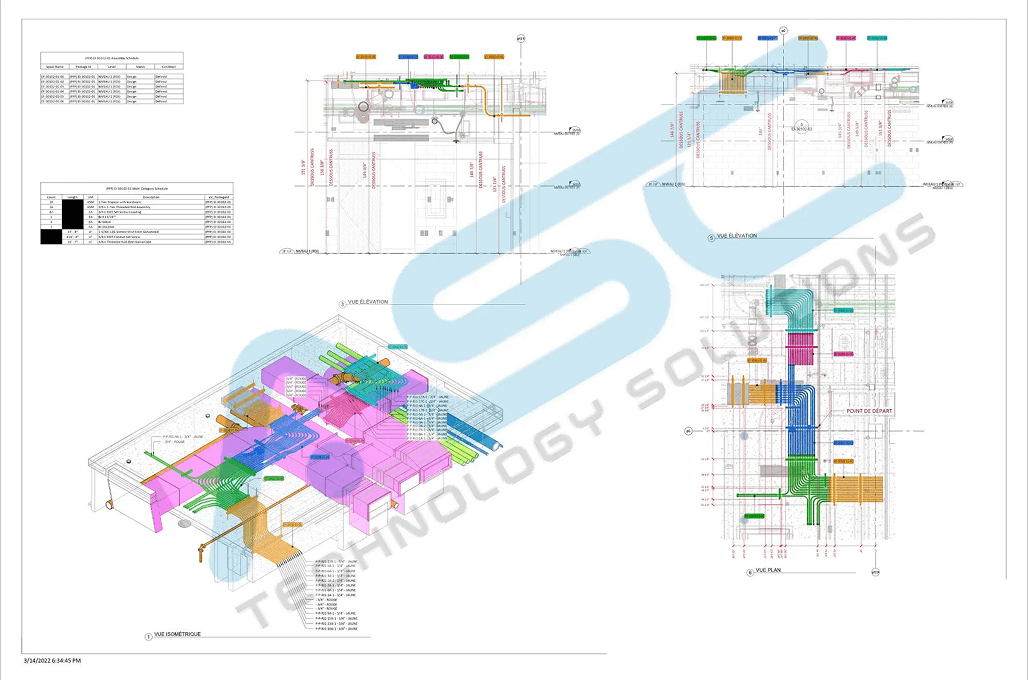

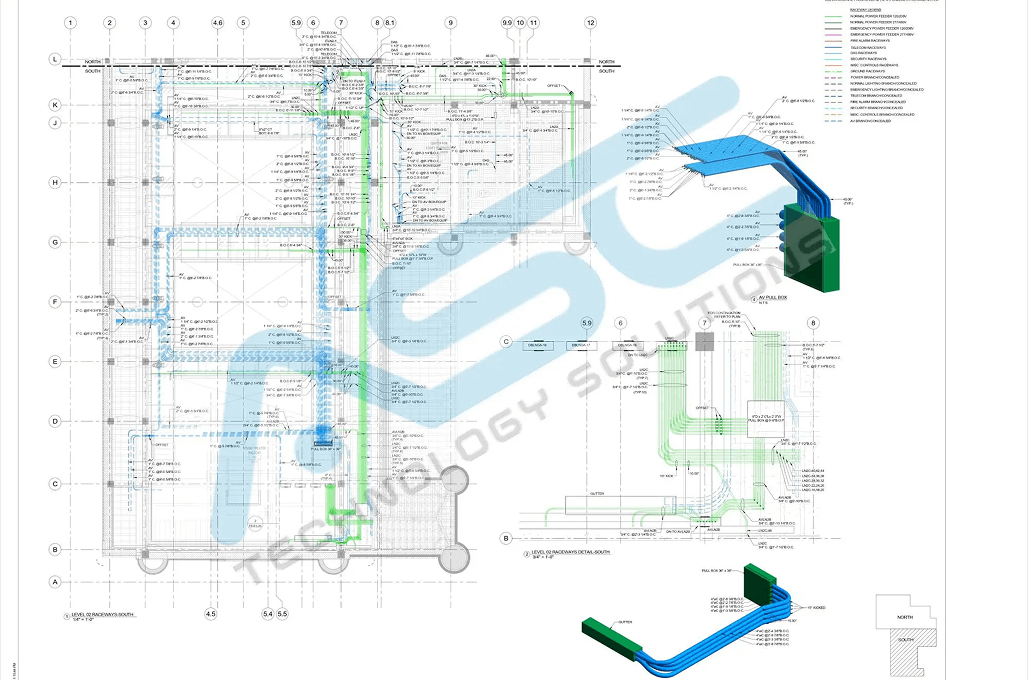

Model insights

Sample Drawings

Take a closer look at our sample drawings to see how we transform complex project requirements into clear, precise outputs.

Your Guide

FAQ

Electrical BIM is a computerized process whereby smart 3D models are used in designing, visualization, coordination, and control of the entire electrical systems in a building project. It involves the integration of electrical engineering information into a 3D interactive environment, unlike traditional 2D CAD, which enhances accuracy and efficiency throughout the building lifecycle.

Electrical BIM has a number of significant enhancements:

- Improved Cooperation: It enables architects, structural engineers, and MEP (mechanical, electrical, and plumbing) teams to work on one model in real-time, and simultaneously, it allows them to communicate with all stakeholders.

- Clash Detection: The process allows detection and resolution of clashes (between the electrical systems and other building components) in a virtual environment before on-site changes and delays (the latter being costly) need to be re-performed.

- Greater Accuracy and efficiency: Because of the detailed 3D visualization, the planning is better, the material takeoffs (Bill of Materials/Quantities) are more accurate, and the components can be prefabricated off-site, and thus the process of installation is simplified.

- Information-Enriched Documentation: BIM models can be information-intensive and hence can be used to create detailed construction documentation, schedules, and reports using model information.

The BIM has the capability of modeling all types of electrical and low-voltage systems, such as:

- Lighting (fixtures, lighting controls, and arrangements of wiring).

- The networks of power distribution (switchboards, panels, power transformers, bus ducts).

- Cable trays and conduits, Cable containment (containers).

- Fire alarm systems

- Data and communication networks (networking components, CCTV).

Yes. Although it is extremely useful in a large and complex project, BIM could be implemented in small and medium projects, considering future maintenance/scalability, energy efficiency analysis, and disaster MEP coordination.

The usual obstacles are an initial entry cost of software, hardware, and training, a long learning curve among staff, and cultural resistance to replacing traditional 2D operations with a 3D team-driven process.

The implementation best practices are:

- Begin with a small pilot project and perform testing on the workflows.

- Choose the hardware and software appropriately.

- Educate employees on modeling and coordination best practices.

- Set up the project objective and methods of communication with all stakeholders involved.

- Make sure that the design involved does not violate pertinent codes and standards such as the National Electrical Code (NEC) or the ISO 19650 standards.