In today’s manufacturing and engineering environment, precision, efficiency, and innovation are important factors for competitiveness. Mechanical drafting services are now recognized as valuable tools for achieving these objectives. Mechanical drafting uses advanced tools and techniques to improve product design, making it correct, efficient, and involving more people. In this blog, we will discuss the importance of mechanical drafting services today, their effectiveness in improving results, and their contribution to developing better products.

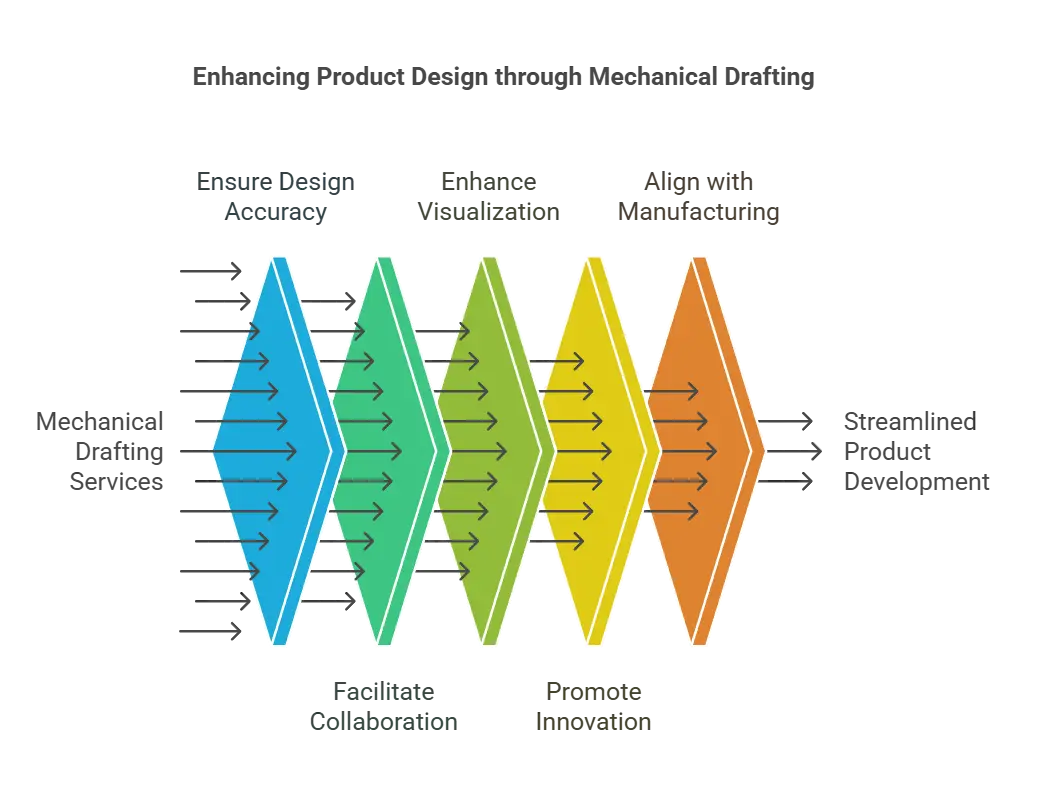

The Role of Mechanical Drafting in Product Design

Mechanical drafting services are essential throughout the concepts to production and at each step of the product development. Here’s how they enhance product design:

1.Precision, and Accuracy in Design

Mechanical drafting makes certain that every part is depicted to the most precise standards of measurement. First, it will remove all chances of ambiguity since accurate drawings are produced to guide the manufacturing process. Engineers can make specification documents containing a description of dimensions, allowable variations in dimensions, and materials to be used in the manufacture of products.

2.Streamlining Collaboration

Mechanical drafting software allows multilateral drafting by different teams of a company within the same department or branch. With digital design, there is the ability to share the design, review it, and even update it with different parties, designers, engineers, and manufacturers. The sharing of this information is smooth and this leads to faster completion of decisions hence reducing development periods.

3.Improved Graphics with 3D Modeling

Computer-aided drafting has added ingenious features like 3D modeling to take the feel of the product in a real model. Such models help the stakeholders to get an idea of the final product, and look at the possibility of designing flaws and the general aesthetic appeal that is likely to be presented during the final product. Often, 3D models allow designers to perform virtual design and realize products, which reduces the need for physical models and expenses.

4.Coordinating Innovation and Personalisation

Mechanical drafting also contributes to design evolution, referring to an iterative process, which allows the engineer to try some idea and determine its practical applicability without much delay. Using these tools, the designs are easily made to suit the specifications of the client or to suit the prevailing market trends. It promotes innovation in practice whilst also ensuring that, as an organization, it remains as efficient and effective as possible.

5.Manufacturing Processes Interfaces

Mechanical drafting makes certain that designs will conform to manufacturing specifications and constraints. They can prepare complex production drawings that include the sequence of assembling the product, materials used, and recommendations on quality control. This alignment with the manufacturing process cuts on wastage, and variations, and guarantees that items are created in the right manner.

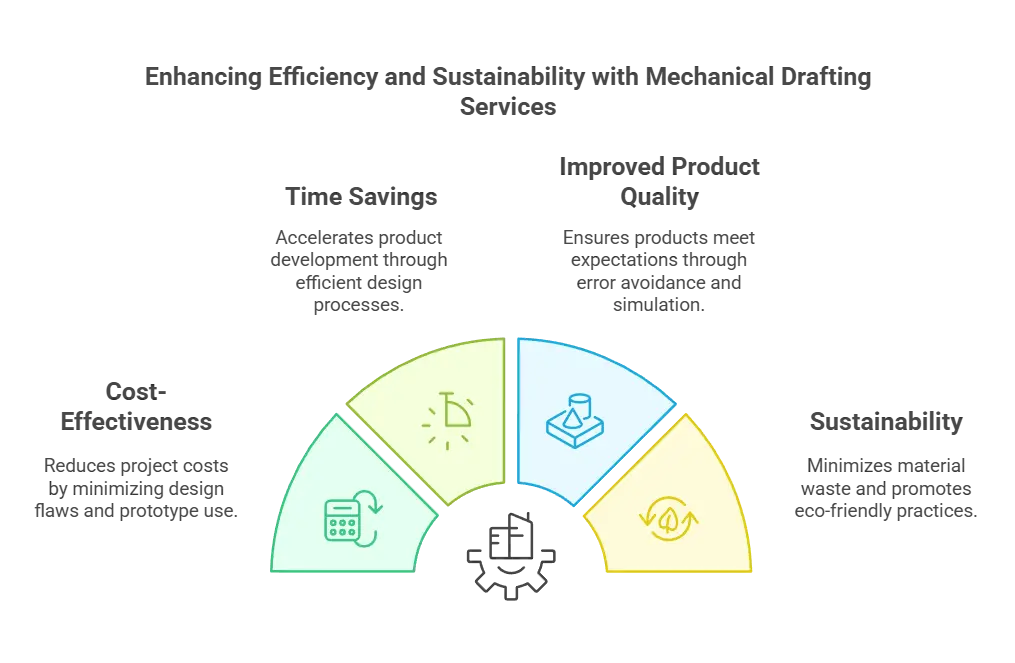

Key Benefits of Mechanical Drafting Services

- Cost-Effectiveness

Through early identification of design flaws and minimizing the use of physical prototypes, mechanical drafting has been shown to decrease the total costs of a project. It also becomes possible to manage resources effectively during the production of the product.

- Time Savings

Computer-aided design products facilitate design production in this manner; the engineers have time to draw, invent, and find solutions. Sprint cycles and frequent modification of plans also help to cut response time and develop products faster.

- Improved Product Quality

Proper drafting helps to avoid errors that may occur and thus products must work as expected or even better. Simulation can also be employed to evaluate design under different loads to establish the durability of the actual product.

- Sustainability

Mechanical drafting uses less material and it ensures that there is less wastage which is good for the environment. Professionals in this field can search for sustainable materials and practises, therefore playing a part in designing more environmentally friendly products.

The Future of Mechanical Drafting Services

The field of mechanical drafting is still on the brink of change as more innovations, and technologies are developed. AI and machine learning are being incorporated into drafting software to perform fairly repetitive exercises and to propose rational options for design. There is increased integration of cloud-based applications in facilitating collaboration, and new improvements in the integration of AR and VR in design reviews.

With these advanced technologies in their development stage, mechanical drafting services shall have a more significant input in product development. They will provide engineers with the tools necessary to come up with new, quality products, in a shorter time and with less cost.

Conclusion

Mechanical drafting services represent one of the cornerstones of contemporary product design values, promising nothing but a blazing pace, accuracy, and invention. From the beginning till the end of the process of manufacturing, all drafting tools guarantee that the designs are correct, feasible to render, and conform to market benchmarks. The application of modern approaches to product development via efficient drafting contributes to better results and successful diffusion in a competitive environment. Mechanical drafting is one of the oldest domains that have played an important role in the growth of the engineering industry; in the future, mechanical drafting will still be instrumental in producing better products to suit the changing world.

Leading BIM services provider. Adding Innovation and Excellence to the BIM Services.