Mechanical Coordination Services

Mechanical Coordination Excellence for Streamlined Workflows

Comprehensive Mechanical Coordination Services for Seamless Project Execution

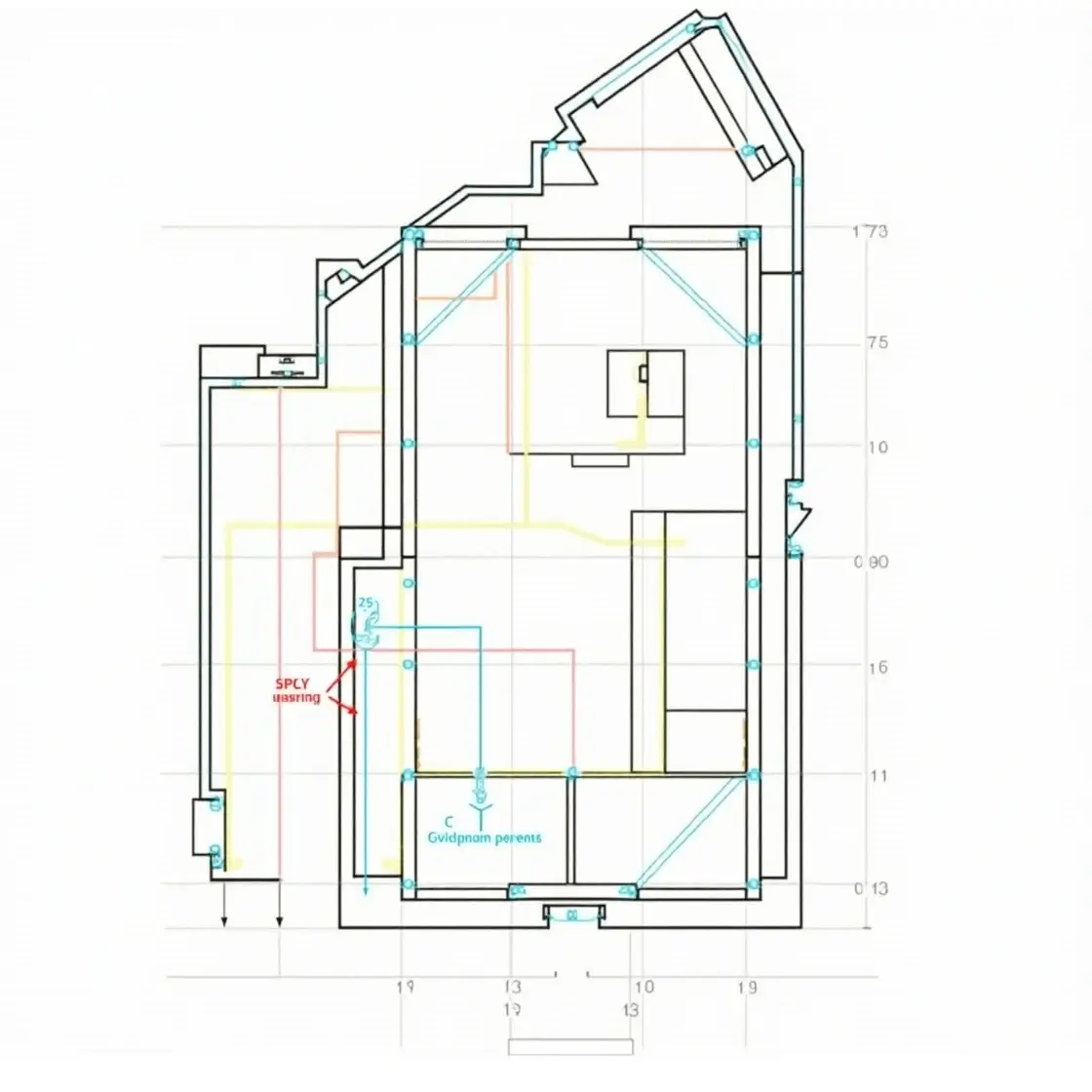

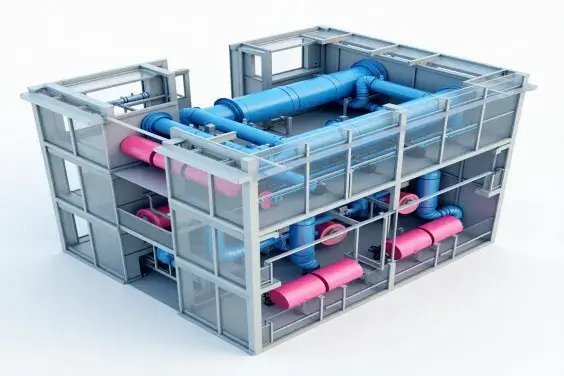

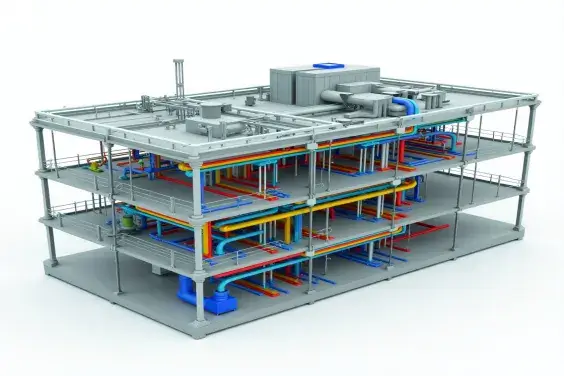

Preventive planning at ASC Software Solutions remains essential throughout the building design stages, including schematic design, design documents, and construction documents for our mechanical coordination services that prevent future problems from occurring. The specialists at ASC verify that all systems integrate seamlessly with other building systems to avoid time-consuming reworks and schedule delays. By employing BIM (Building Information Modeling) technologies, we detect complex hard and soft clashes involving HVAC equipment and distribution networks, which we subsequently address through precise analyses. The list of components includes cooling towers, air handling units (AHUs), ductwork, exhaust fans, diffusers, heaters, AC units, and other mechanical components. The level of detailed coordination during the design phase reduces mistakes before construction, thus delivering better efficiency, decreased costs, and shortened project durations.

Collaborative Mechanical Coordination for Optimised System Performance

Our mechanical coordination procedure provides support for system performance optimisation through strategic teamwork. The company coordinates building system operations by working directly with mechanical subcontractors, general contractors, architects, structural engineers, and MEP teams. The consultative method of our approach helps mechanical designers and subcontractors make design modifications after they gain an informed understanding of industry standards and best practices. Our platform provides real-time updates alongside 3D modeling functions that enable stakeholders to watch for potential problems ahead of time, which benefits multidisciplinary coordination. Partnering with ASC Software Solutions means gaining access to expert insights, innovative technology, and a dedicated team that prioritises precision, efficiency, and excellence in mechanical coordination.

Innovative Mechanical Coordination for Cost-Effective Construction

ASC’s Mechanical Coordination services: The Key to Efficient MEP Integration

Comprehensive MEP BIM services for contractors

Mechanical Model Creation

We develop complex mechanical system models at LOD 100 to 500, which integrate electrical, plumbing, and base architectural and structural models. The specific nature of our modeling helps increase the coordination potential between project teams, and the accuracy level during construction planning.

Coordination Ownership

The mechanical design team engages in on-site gatekeeper meetings for coordination discussions to help mechanical designers execute their systems from schematic design through construction stages.

Clash Report Generation

Our team employs advanced tools for clash detection to check for mechanical design conflicts that exist between system models. The generated clash reports lead to the identification of issues, which helps prevent construction delays and reduces rework.

Design Modification

We make design modifications based on coordination meetings, further refining and integrating the mechanical system models. A complete coordinated construction model emerges as the outcome, promoting efficiency and meeting project specifications.

Benefits of outsourcing Mechanical Coordination Services

Commitment to Excellence in Mechanical Coordination Services

- Construction efficiency relies on solving initial spatial conflicts that emerge between mechanical, electrical, and plumbing components while preventing modifications during the construction stage. The process yields minimal errors, which in turn optimises space usage efficiency.

- When MEP components undergo thorough coordination within a model design, it reduces material waste and eliminates avoidable rework, thus decreasing project expenses. Project execution becomes more cost-effective through the combination of optimised workflows and early detection of clashes that maintain project quality standards.

- The detailed sectional views extracted from BIM models help contractors and engineers create a better understanding of mechanical layout designs. The planning process becomes more precise because mechanical components fit perfectly into the structural system design.

- Construction delays are prevented because the clash detection software reveals possible conflicts that can be resolved before construction starts. This preventative measure saves building time while enabling crews to work efficiently during construction.

Why Choose Us for Your Mechanical Coordination Services

Subject Matter Expertise

Our team is well-versed in what they do. They are conversant with the local codal provision and understand industry-specific standards.

Working In Your Timezone

Often we see our clients want to be connected to the team they are working with for better and quick communication. Hence we work on your timezone.

Competitive Pricing

We offer competitive pricing starting from $16 per hour depending on the project scale, resource type and scope of the projects

Robust IT Infrastructure

Data-secured FTP, licensed and the latest version of hardware and software toolset ensures error-free designing, modeling, and overall project execution process, diminishing technical glitches.

Training & Development

Arrangement of multiple training and development programs for our engineers to upgrade their software skills and update with the latest technology ensures a premium client experience.

Policy

Contract agreements before project kick-off and standard guidelines eliminate miscommunication and ensure a constructive approach toward business relationships.

- All

- Architectural

- Mechanical

- Plumbing

Our Projects

Frequently Asked Questions

What is Mechanical Coordination in construction?

The construction process of mechanical coordination brings HVAC systems together with electrical plumbing, and structural elements to create integrated mechanical solutions. The process ensures efficient component design and installation, which avoids conflicts between systems to achieve better project operation.

Why is Mechanical Coordination important in MEP projects?

MEP projects require Mechanical Coordination because this critical element prevents spatial conflicts and improves system layouts and project operational efficiency. This maintains perfect coordination between different building elements, which reduces construction delays and prevents redo work, and results in superior final project quality.

How does mechanical coordination help with clash detection?

Mechanical Coordination enables pre-construction detection of mechanical component conflicts that exist between these elements and the building’s other construction components. The detection of potential design conflicts using BIM software enables developers to make changes which avoid the occurrence of costly errors and project delays.

How does Architectural 3D Modeling improve construction efficiency?

The visual presentation of elements through 3D modeling improves Mechanical Coordination because it shows mechanical systems inside the full building framework. Through this tool stakeholders can view spatial interactions while uncovering overlaps as well as position elements effectively and enhance team communications, which drives the project forward more efficiently.

What are the cost-saving benefits of Mechanical Coordination Services?

The implementation of Mechanical Coordination Services results in cost reduction through controlled material usage, avoidance of reinspection costs and enhanced installation optimisation efficiency. Early conflict detection leads to lower on-site modification expenses and workflow coordination minimises labor needs and project duration.

How does BIM support Mechanical Coordination?

Through Building Information Modeling (BIM), Mechanical Coordination generates an all-inclusive digital model which unifies mechanical, electrical and plumbing systems. The system allows instant team connections, accurate conflict identification and seamless project scheduling, which produces an error-free construction path.

What is the role of a Mechanical Coordinator in a construction project?

At a construction project, the Mechanical Coordinator takes charge of bringing mechanical systems together with building components. Mechanical coordinators complete design reviews as well as conduct clash detection testing to work with various teams for successful integration of mechanical systems that meet project requirements and schedules. The role they perform brings efficiency to operations while reducing risks and maintaining industry standards.